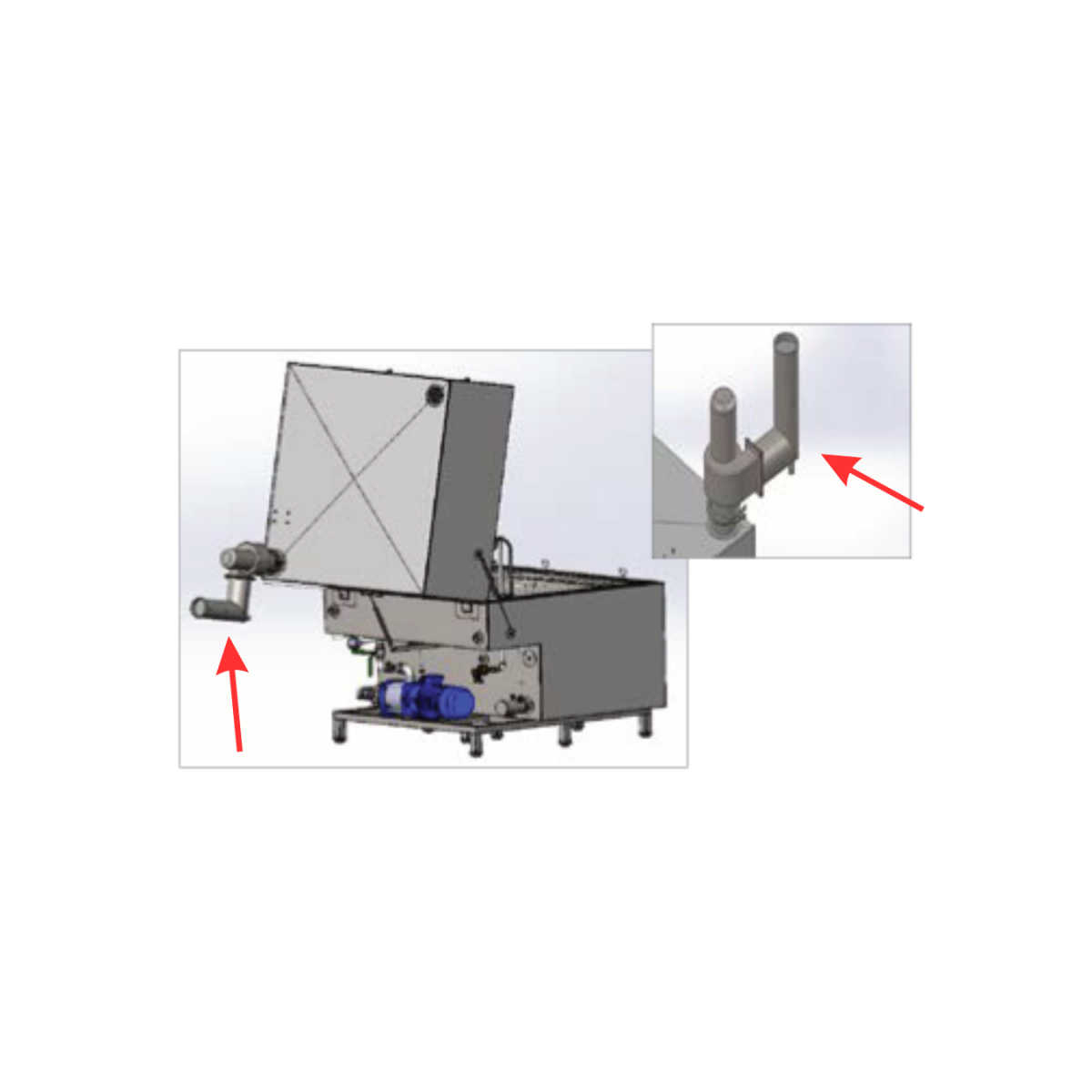

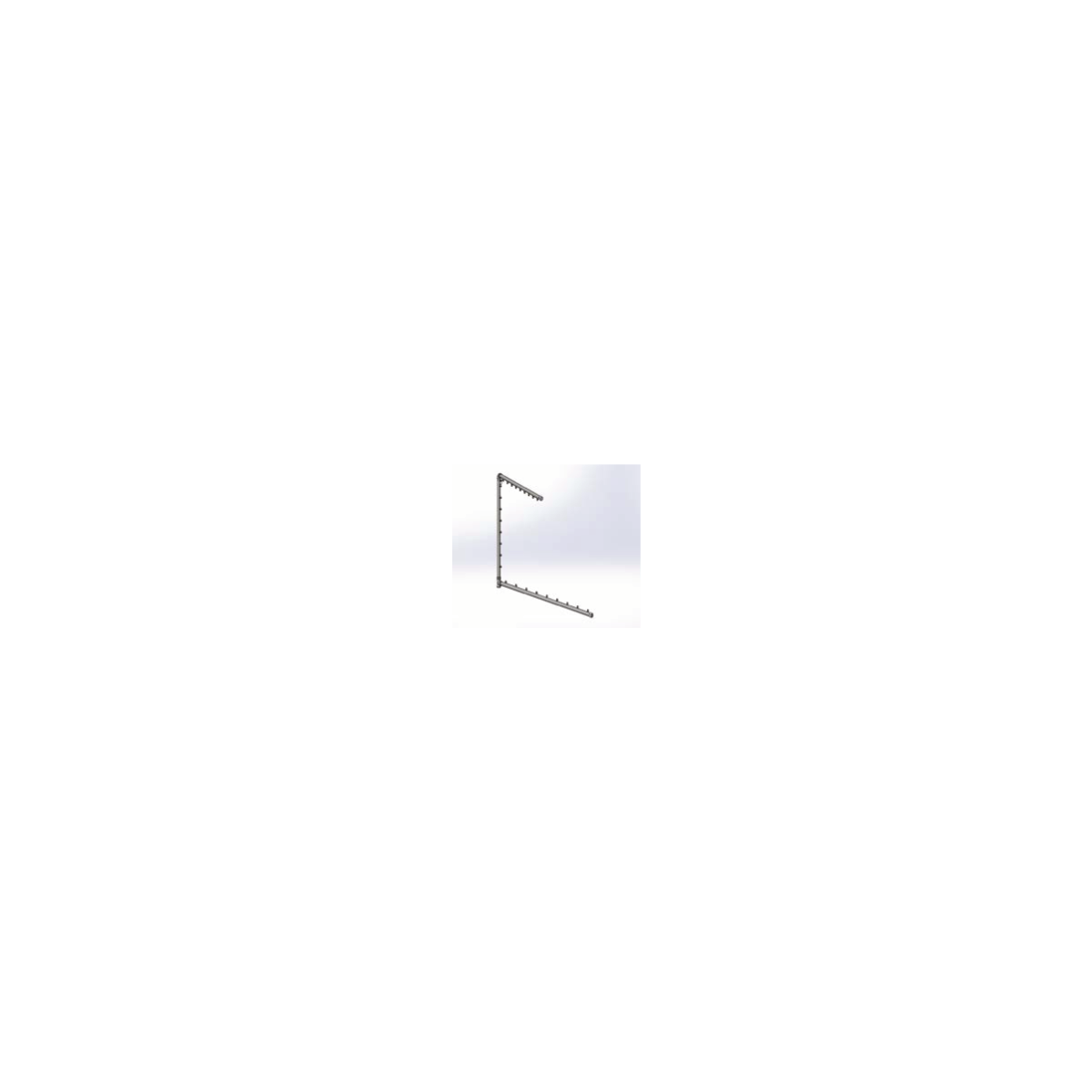

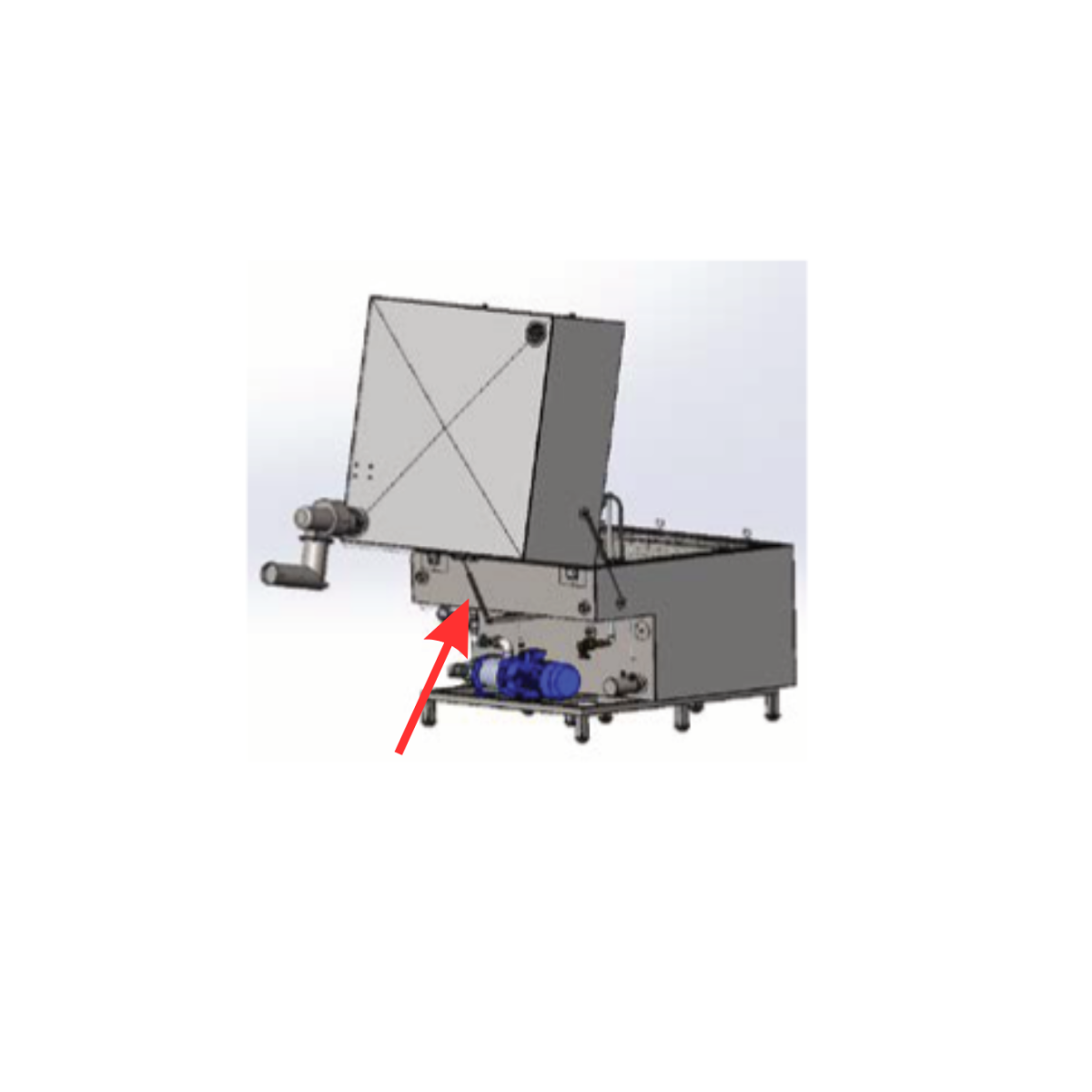

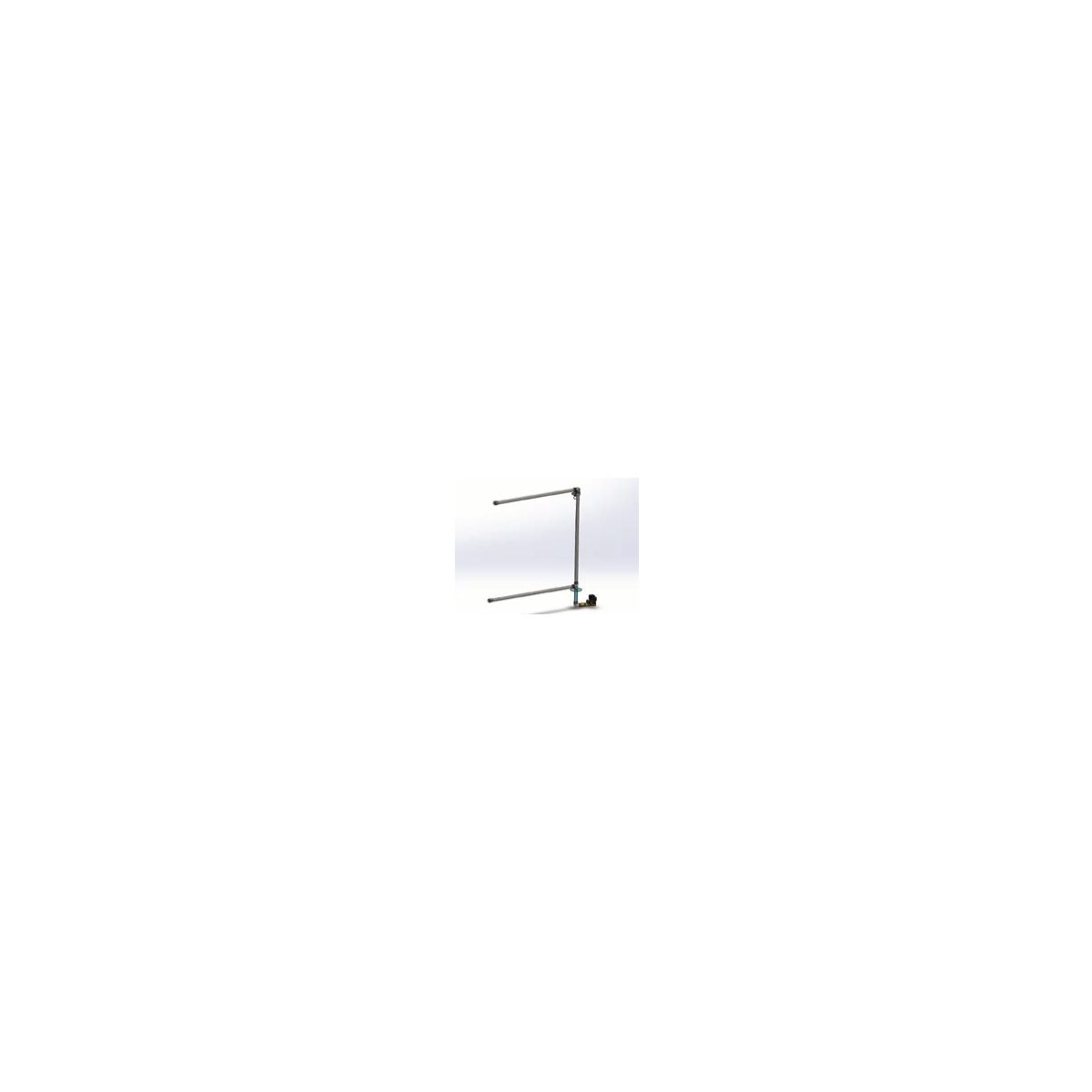

Optional accessories for the LCT HTW 1000

3.492,65 € *

3.492,65 € per 1

Question about item

Stck

Recently viewed